Products

- Rice noodle processing

- KR1 Instant Flat Rice Noodle (Kwui Tiew) Productio

- KR2 Instant Rice Vermicelli Production Line

- KR3 Rice Wave Noodle Production Line

- KR4 Rice Stick Noodle Production Line

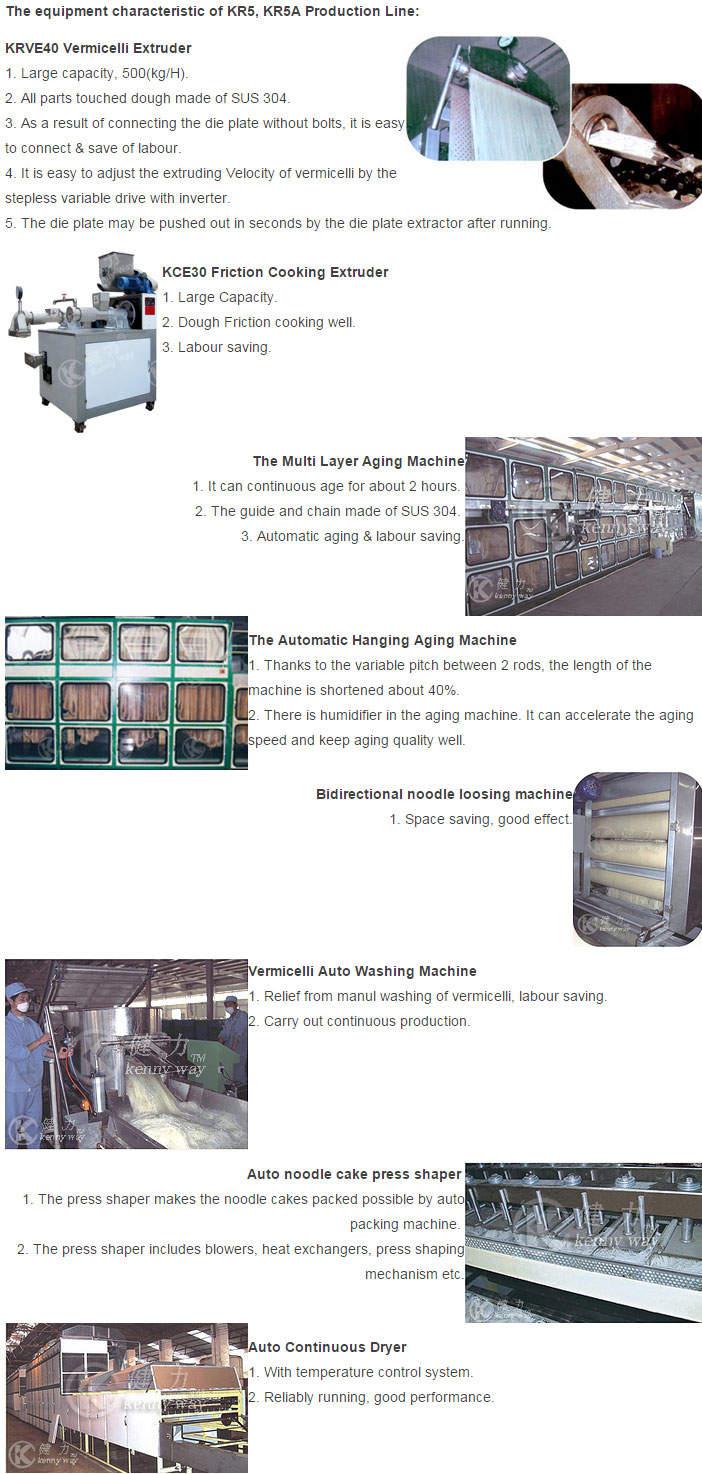

- KR5, KR5A Friction Cooking Rice Noodle Production

- KR6 Short Goods of Macaroni Production Line

- KR7 Fresh Rice Noodle Production Line

- KR8 Straight Rice Noodle Production Line

- Starch noodle processing

- Non-fried flour noodle processing

- Single Machine

- Mini fresh rice noodle machine

- Vermicelli extruder

- Grinder

- Mixer

- Dehydrator

- Dryer

- Aging machine

- Cutting machine

- Vermicelli washing machine

- Noodle loosing machine

- Rice liquid tank

- Feeding machine

- Auto noodle cake press shaper

- Rice distribution machine

- Dough breaker

- Water jet rice washing rice soaking and sand

- Sheet steamer

- Auto rice washing soaking and grinding system